Low Noise

The tire shredding machine provides a quieter and more comfortable working environment by minimizing vibrations with its solid and balanced structure.

Versatility

The tire shredding machine is capable of processing different types of tires, making it suitable for a variety of industries.

Long Maintenance Intervals

The tire shredder allows you to work uninterruptedly with long maintenance intervals.

Flexibility

The tire shredding machine has a wide range of tire processing capacity, making it suitable for different tire applications.

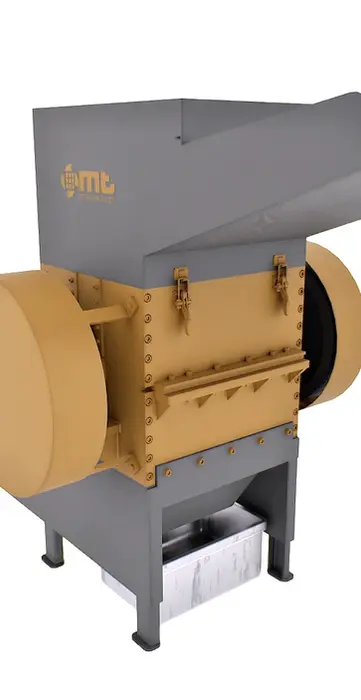

Wear-Resistant Blades

The tire shredding machine offers long-term and effective shredding with its blades made of high-quality steel.

High Efficiency

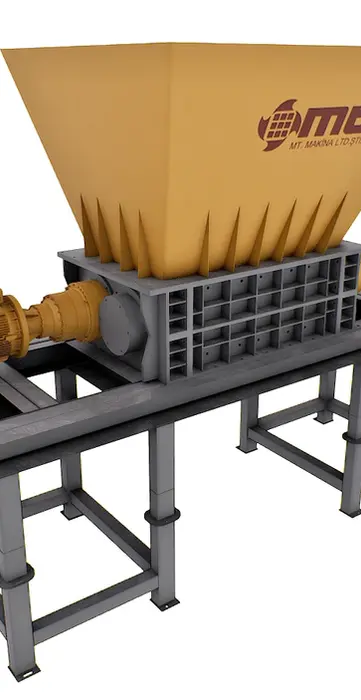

The tire shredder shreds tires quickly and effectively using a combination of high torque and low speed with its dual shaft design.

Quick Blade Change

The tire shredder machine allows you to work uninterruptedly thanks to its easily replaceable cutting blades.

Easy to Use

The tire shredder machine can be easily operated thanks to its user-friendly control panel and simple design.

Tire Shredding Machine Speeds Up Recycling Processes for Old Car Tires

Did you know that more than a billion tires are thrown away each year worldwide? This amounts to approximately 13 million tons of scrap tire waste. Tire recycling is a critical solution to prevent environmental pollution and regain valuable resources. Tires are made up of a mixture of materials such as rubber, steel, and fiber, which make them both strong and durable. However, when waste tires are not recycled correctly, they can cause great harm to the environment. With a waste tire recycling facility, these tires can be processed to protect the environment and reuse these materials. MT Makina offers high-performance tire shredding machines for tire recycling.

By using a tire shredding machine, rubber, steel and other materials in tires are separated and recycled. The tire shredding machine performs the tire shredding process reliably and efficiently. Car tire recycling companies and waste tire recycling facilities effectively recycle scrap car tires with tire shredding machines. As MT Makina, we accelerate the recycling of vehicle tires thanks to the tire shredding machine we developed.

Separating materials such as rubber and steel wire inside scrap tires can be quite a challenging process. For this reason, MT Makina offers strong and durable solutions for scrap tire recycling with its scrap tire crushing machines. Tire crushing machines are designed to be both extremely durable and energy efficient. This provides economic advantages especially for tire recycling companies.

In old car tire recycling and old tire recycling processes, the reusability of steel and rubber materials inside tires is an important step in the recycling sector. Waste tire recycling facilities make a great contribution to sustainability by doing this process efficiently. The cost of establishing a tire recycling facility can offer great gains in the long term thanks to the recovered materials.

MT Makina has a leading role in the recycling sector with its tire recycling facilities exported to more than 40 countries worldwide. Tire recycling prices may vary depending on the size of the facilities and the technology used. Tire shredding machines manufactured in accordance with high quality standards are designed to operate with long life and high efficiency. Using advanced technologies such as pyrolysis tire recycling facilities, the recycling of end-of-life tires is made efficient.

Tire recycling plants make significant contributions to environmental protection and economic sustainability. The cost of a tire recycling plant varies depending on the technology used in the installation and operation phase. As MT Makina, we offer our customers all kinds of tire recycling plant installation, regular maintenance, spare parts and technical support services. Waste tire recycling contributes to the environment with the cost of a tire recycling plant installation and offers businesses an economic opportunity.

The tire shredding machine offered by MT Makina provides the most efficient and economical solutions for tire recycling facilities. We make a difference with high-performance tire shredding machines in rubber recycling facilities and waste recycling projects. Recycling tires and scrap tire recycling provides reusable resources with an environmentally friendly process and contributes to the industrial economy.

Turn Waste Into Value with High-Tech Tire Shredder Machines

The tire shredding machine is one of the most effective recycling tools that contribute greatly to the environment. In used tire recycling processes, large-volume waste such as end-of-life car tires are reduced significantly, significantly reducing both storage and transportation costs. Shredded tires obtained through tire recycling can be used as a valuable resource in different areas such as road construction, construction materials and energy production. In tire recycling plant processes, waste management becomes more efficient thanks to the tire shredding machine.

Scrap tires recycled with a tire shredder can be used in energy production facilities as an alternative fuel source. This method contributes to a more sustainable energy production by reducing fossil fuel use. Old tire recycling processes are of great importance for the automotive industry and the protection of natural resources by recycling car tires.

The tire shredding machine offered by MT Makina offers revolutionary technological solutions in the recycling process. Drawing attention with its high performance and durable structure, the scrap tire shredding machine not only processes waste, but also enables the reuse of these wastes in different sectors. Recycled tire products processed with the tire shredding machine can be used as materials in the construction sector and can also be evaluated as an alternative fuel source in energy production. This process emphasizes the importance of waste tire recycling plant technology in terms of environmental sustainability.

MT Makina offers advanced technology for an environmentally friendly, efficient and sustainable future with its tire shredding machine solutions. We offer high-efficiency machines and rubber recycling facilities and tire conversion factory solutions in areas such as waste tire recycling, recycling car tires, scrap auto tire recycling, waste recycling, pyrolysis tire recycling facility, scrap tire crushing machine and recycling of end-of-life tires.

You can contact us to get more information about tire recycling companies, tire recycling prices, tire recycling facility establishment cost, tire recycling facility cost or tire conversion facility establishment cost, and improve your business processes with environmental technology. MT Makina helps you contribute to the environment and your sustainability goals with tire recycling solutions.

Protection of Natural Resources by Recycling End-of-Life Tires

Tire Shredder Machine Performance and Efficiency

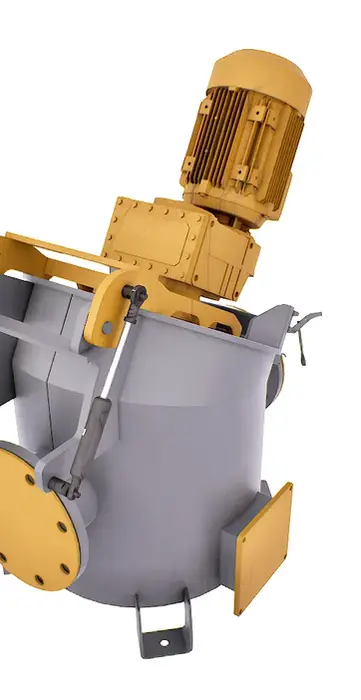

Double Shaft Design

The double shaft tire shredder efficiently processes large tire waste with high torque and minimizes the risk of compaction.

Energy Efficiency

Tire shredding machine engines and systems that provide high energy efficiency reduce operating costs while also reducing environmental impacts.

Long Lasting Knives

High-quality steel blades are wear-resistant for the tire shredder and ensure long-term use.

Flexibility

The tire shredder provides flexibility for different tires and applications with its interchangeable blades and screen systems.

Efficient Tire Shredder Machine Technologies for Recycling Old Tires

The tire shredder machine operates at capacities ranging from 500 kg to 30,000 kg per hour, recycling large amounts of tires. This high capacity speeds up car tire recycling processes, providing significant efficiency for tire recycling facilities. The tire shredder speeds up the recycling process and makes waste management easier and more environmentally friendly.

The tire shredding machine used in the recycling process of car tires is manufactured with durable steel and high-quality materials. In this way, the tire shredding machine is long-lasting and resistant to intensive use. It provides cost efficiency for car tire recycling companies and waste tire recycling facilities and shortens the return on investment period.

The tire shredder is equipped with blades that can easily cut the hard structure of tires and maintain their sharpness for a long time. It overcomes even the most difficult scrap tires in old tire recycling processes. It offers an environmentally friendly and economical solution thanks to its energy-saving design in used tire recycling processes. The tire shredder minimizes energy consumption, reducing operating costs and environmental impacts.

With its ergonomic design and user-friendly interface, the tire shredder machine offers easy use for operators. It also speeds up maintenance processes and ensures that the tire shredder has a longer life. The scrap tire shredder machine shows high performance in difficult processes such as scrap car tire recycling and is an ideal tool for rubber recycling facilities.

Tire recycling companies can speed up the recycling of vehicle tires, old car tire recycling, recycling of end-of-life tires and waste recycling processes with the tire crushing machine. An effective recycling process can be provided with a scrap tire shredding machine in facilities such as tire recycling factories and pyrolysis tire recycling facilities. Offering economical solutions regarding tire recycling facility costs and tire recycling facility installation, MT Makina helps you optimize your waste management processes with environmentally friendly recycling technologies.

Mobile Crusher | Single Shaft and Double Shaft Solutions

The pallet shredder is a cutting-edge system developed for the safe, rapid, and efficient reduction of wooden pallets generated in industrial areas. Available in various models to suit varying capacities and needs, these machines easily process even the most difficult pallet waste thanks to their powerful rotor structure and specialized blade technology. The shredding system, with its high-torque motor and durable blades, reduces pallets to smaller sizes, ensuring hygiene and significantly reducing waste volume. This reduces storage and transportation costs while also supporting environmental sustainability.

Additionally, shredded pallet waste can be repurposed for biomass energy production, fuel preparation, or recycling processes. Standing out with its durable construction, long-lasting performance, and low energy consumption, the pallet shredder is an ideal solution for production facilities, recycling centers, and logistics storage areas. It provides businesses with high productivity by safely processing not only wooden pallets but also packaging waste and similar materials. Pallet shredder prices offer economic advantages for businesses. By combining high-capacity shredding functions in a single device, it reduces both investment and operating costs. It is a powerful, reliable, and environmentally friendly option for long-term and sustainable waste management.

Mobile Crusher

Technical Specifications

TSV-140

Shredding Area: 1400 x 400 mm

Rotor Length: 1400 mm

Engine Power: 30 kW

TSV-200

Shredding Area: 2000 x 400 mm

Rotor Length: 2000 mm

Engine Power: 55 kW

TSVX-200

Shredding Area: 2000 x 400 mm

Rotor Length: 2000 mm

Engine Power: 45 x 2 kW

OPTIONAL FEATURES

Dual-Engine Design

Mobile Design

Metal Separator

Rotor Cooling System

Automatic Lubrication Unit

Sieves in Different Sizes

Conveyor Screw Applications for Exit

.webp)

Tire Shredder Machine Video Gallery

Watch how car, truck and tractor tires are processed efficiently in our tire shredder video gallery. Developed for recycling and waste management, these machines are powerful, safe and quiet with a high-torque cutting system. Discover systems that stand out with their rubber recovery, environmentally friendly design and low maintenance costs.

.webp)