High Efficiency in Industrial Waste Management with the Double Shaft Shredding Machine

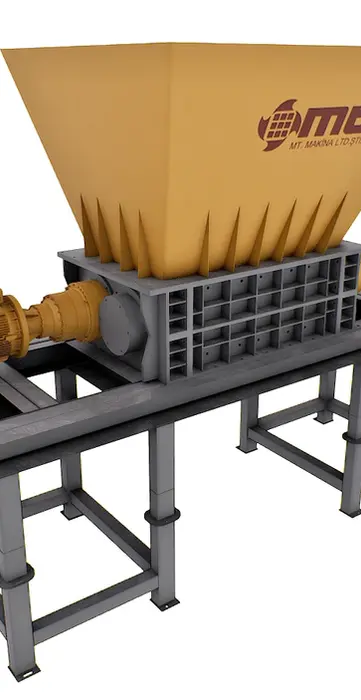

One of the biggest challenges faced in industrial waste management and recycling processes is the efficient processing of different material types. A dual-shaft shredder overcomes this challenge by combining high torque and low speed to effectively shred even the toughest materials. Offering a wide range of applications, including plastic shredders, metal shredders, tire shredders, wood shredders, glass shredders, and household waste shredders, this system plays a critical role in recycling processes.

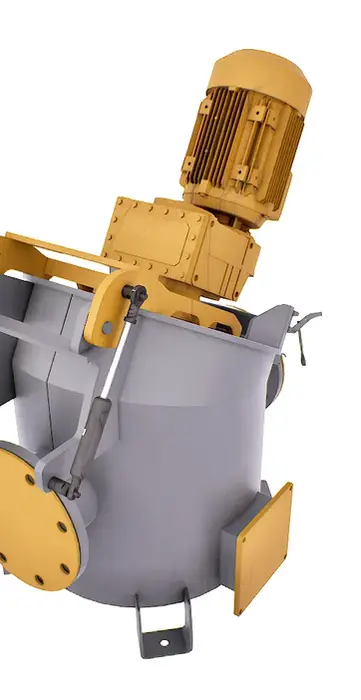

The CS-Series dual-shaft shredder, with its robust steel blades and powerful motors, efficiently processes various types of waste in machines such as scrap plastic shredders, paper shredders, and pallet shredders, delivering durable performance. The shredder operates at low speeds, reducing vibration and providing an environmentally friendly solution. In applications such as scrap tire shredders and PVC shredders, the low rotation speed minimizes dust emissions, protecting the environment.

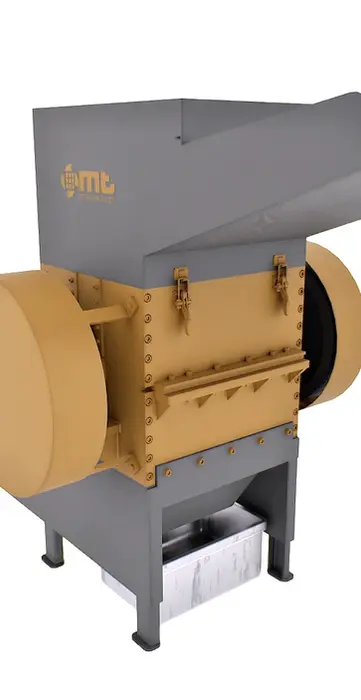

The dual-shaft solid waste shredder simplifies maintenance with its modular rotor and bearing design. It increases efficiency and reduces operating costs in various machines, such as metal shredders, pallet shredders, and fabric shredders. Thanks to its energy-efficient inverter-controlled motors and automatic reversing features, the shredder optimizes energy costs, providing businesses with economic advantages.

Machines such as recycling crushers, PET bottle shredders, and bale shredders stand out for their ability to process a variety of materials, including plastic, metal, tires, wood, glass, and household waste. Machines such as metal shredders, scrap iron shredders, and scrap car shredders promote sustainability in industrial waste management. Furthermore, they offer economical solutions in terms of shredder prices, metal shredder prices, and scrap iron shredder prices. The double-shaft shredder delivers high performance to businesses, promoting environmental sustainability and becoming an indispensable tool in modern waste management.

Advantages of Double Shaft Solid Waste Shredding Machine

The dual-shaft solid waste shredder offers a wide range of applications thanks to its ability to process a variety of materials. It is suitable for a variety of industries, including plastic shredders, fabric shredders, pallet shredders, paper shredders, medical waste, and electronic waste. Its durable construction and long maintenance intervals ensure uninterrupted operation, reducing operating costs and increasing productivity. Easily replaceable blades on machines like plastic shredders and pallet shredders ensure quick and efficient maintenance.

This high-capacity, dual-shaft shredder increases operational efficiency while minimizing downtime and maintenance costs in applications such as plastic shredders, PET bottle shredders, and scrap plastic shredders. This system, which works with machines such as paper shredders and PVC shredders, maximizes operator safety with its advanced safety features.

In waste reduction and recycling processes like cardboard shredders, food shredders, and scrap tire shredders, dual-shaft shredders promote environmental sustainability and offer a powerful solution for waste management. They also deliver long-lasting and reliable performance in applications like shredders, bale shredders, and metal shredders. They also offer economic advantages in terms of solid waste shredder prices, pallet shredder prices, and scrap iron shredder prices. By offering high efficiency and sustainability in recycling and waste management processes, shredders offer an ideal solution for businesses looking to adopt an environmentally friendly approach.

Energy Efficiency and Durability Combined with the Double Shaft Shredding Machine

Double Shaft Shredding Machine Performance and Efficiency

Ability to Process Different Materials

The double shaft shredder can process a variety of materials, including plastic, metal, wood, paper and medical waste.

High Torque and Low Speed

The double shaft shredder effectively shreds tough materials with high torque and low speed.

.webp)

Durable Blade Steels

The double shaft shredder provides long-lasting and efficient use with its durable blade steels.

.webp)

Easy Maintenance

Thanks to its modular design, the twin-shaft shredder enables quick replacement of components, which reduces maintenance times.

Increased Efficiency in Industrial Waste Management with a Double Shaft Shredding Machine

Double-shaft shredders provide high efficiency in industrial waste management and recycling processes. Machines such as plastic shredders, metal shredders, wood shredders, and fabric shredders contribute to recycling processes by processing a variety of materials quickly and effectively. With high torque and robust construction, the double-shaft shredder reduces waste volume by shredding difficult materials, minimizing operating costs with low energy consumption and long maintenance intervals.

The double-shaft shredder processes large volumes of waste, such as municipal waste, household waste, and construction waste, and functions as a recycling shredder, PET bottle shredder, and scrap plastic shredder. Offering an excellent solution for processing plastic, metal, wood, and paper materials, the double-shaft shredder can be used in conjunction with pallet shredders, paper shredders, and tire shredders to speed up the recycling process.

The dual-shaft shredder, with its energy-efficient motors and optimized cutter geometry, offers economical solutions for solid waste shredding. By ensuring high efficiency in industrial waste management, the shredder contributes to environmental sustainability and facilitates the achievement of recycling targets.

CS-Double Shaft Solid Waste Shredding Machine

Technical Specifications

CS-20

Shredding Area: 200 x 200 mm

Rotor Length: 200 mm

Engine Power: 2.2–11 kW

CS-40

Shredding Area: 400 x 400 mm

Rotor Length: 400 mm

Engine Power: 5.5–22 kW

CS-60

Shredding Area: 600 x 600 mm

Rotor Length: 600 mm

Engine Power: 11–45 kW (2x)

CS-80

Shredding Area: 800 x 800 mm

Rotor Length: 800 mm

Engine Power: 15–55 kW (2x)

CS-100

Shredding Area: 1000 x 1000 mm

Rotor Length: 1000 mm

Engine Power: 22–90 kW (2x)

CS-120

Shredding Area: 1200 x 1200 mm

Rotor Length: 1200 mm

Engine Power: 30–110 kW (2x)

CS-150

Shredding Area: 1500 x 1200 mm

Rotor Length: 1500 mm

Engine Power: 45–132 kW (2x)

CS-180

Shredding Area: 1800 x 1500 mm

Rotor Length: 1800 mm

Engine Power: 55–132 kW (2x)

CS-200

Shredding Area: 2000 x 1800 mm

Rotor Length: 2000 mm

Engine Power: 75–200 kW (2x)

OPTIONAL FEATURES

Four-Motor Design

Belt Pulley Hydraulic Coupling

Rotor Cooling System

Automatic Lubrication Unit

Hydraulic Press Unit

Sieves in Different Sizes

Bolt-on removable blade design

Hydromotor drive system

Office and industrial type chassis design

Spiral, Conveyor and Transport Fan Applications for Exit

.webp)

Double Shaft Shredding Machine | High Efficiency Waste Management

The double-shaft shredder is a powerful system developed for the safe and efficient reduction of industrial waste. Its high-performance double-shaft design allows it to easily process even the most challenging materials as a solid waste shredder, providing businesses with significant advantages in waste management processes. Equipped with a durable rotor structure and specialized blade technology, the double-shaft shredder offers long-lasting operation while saving energy and reducing operating costs. This combines both high efficiency and economic advantages.

The double-shaft shredder stands out with its versatile applications. It offers a reliable solution for a variety of industrial applications, including cardboard shredders, food shredders, scrap tire shredders, metal shredders, and pallet shredders. It accelerates recycling processes by shredding plastic, metal, wood, textiles, and other types of solid waste. Furthermore, its environmentally friendly design reduces waste by minimizing storage and transportation costs. This supports environmental sustainability and contributes to businesses' recycling goals. It also offers economical solutions in terms of solid waste shredder prices, scrap iron shredder prices, and pallet shredder prices, making it an ideal choice for long-term investments.

.webp)

.webp)

.webp)