.webp)

Flexible Use

The scrap metal shredder has a wide range of applications, from metal recycling plants to automobile recycling.

.webp)

Cost Savings

With its low energy consumption and maintenance costs, the scrap metal shredder offers economic advantages to businesses.

.webp)

Environmental Sustainability

Scrap metal shredders make significant contributions to environmental sustainability by accelerating the metal recycling process.

.webp)

Minimum Maintenance Requirement

Thanks to its robust structure, the scrap metal shredder works smoothly for a long time with minimum maintenance requirement.

.webp)

Automatic Return System

The scrap metal shredder provides uninterrupted operation by preventing jamming with its automatic reversing system in overload situations.

.webp)

User Friendly Design

With its simple control panels and easy-to-use features, the scrap metal shredder machine allows operators to use the machine comfortably.

.webp)

Energy Efficiency

Thanks to its high energy efficiency, the scrap metal shredder reduces operating costs while minimizing environmental impact.

.webp)

Compatible with Various Metals

The scrap metal shredder can process many types of metals, including scrap iron, aluminum, stainless steel, car parts and electronic waste.

.webp)

Durability and Longevity

Equipped with powerful motors and long-lasting blades, the scrap metal shredder is durable even under harsh working conditions.

.webp)

High Efficiency

Scrap metal shredders accelerate the recycling process by shredding metal quickly and effectively.

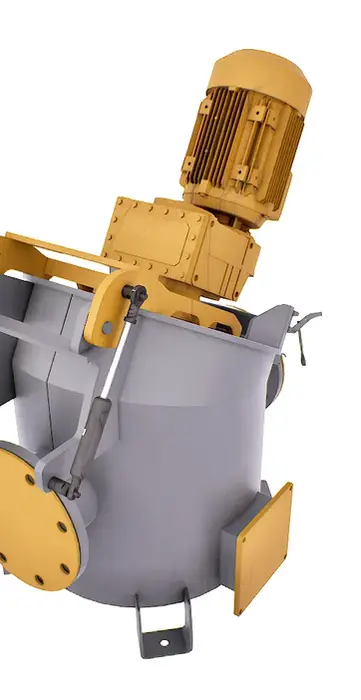

High Efficiency in Recycling with Redmonster Scrap Metal Shredder

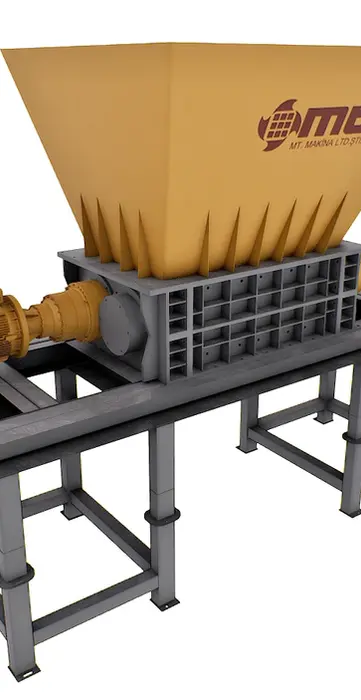

Metal recycling is of great importance in terms of environmental sustainability and economic efficiency. In this process, scrap metal shredder plays a critical role. The double-shaft scrap metal shredder effectively shreds various types of metals, making them suitable for recycling. The scrap metal shredder is capable of processing different types of metals such as scrap iron, aluminum, stainless steel and metal bales, and provides great convenience in industrial waste management.

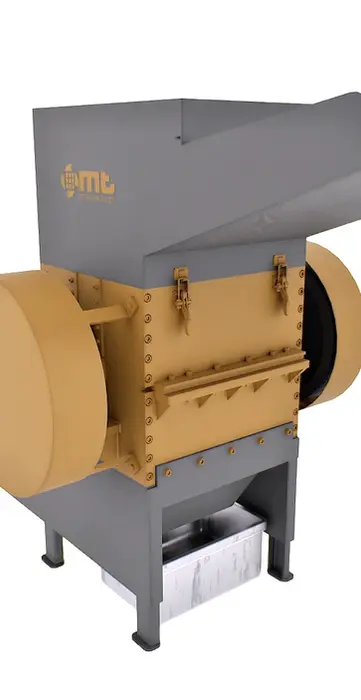

This equipment, which includes different types such as scrap iron shredder and aluminum shredder, attracts attention with its high torque and robust structure. The scrap car shredder provides high efficiency by effectively processing especially large and durable materials. The scrap metal shredder offers long-lasting use with its durable components and powerful hydro motors and is designed for continuous operation. In this way, it can also be used in difficult applications such as car shredder.

Thanks to its modular structure, the scrap metal shredder can be customized according to customer requirements with speed, torque and blade options. Various models, such as the iron shredder, meet different industrial needs. In addition, the scrap car shredder and iron shredder can be easily integrated into existing facilities, allowing operators to use the machine easily and safely. The scrap metal shredder provides safe and uninterrupted operation with its automatic reversing system and overload sensors.

Scrap iron shredder machine prices and metal shredder machine prices may vary depending on the features and capacity of the machines. However, scrap metal shredder machines provide high efficiency and cost advantages to businesses in the long run. Car shredder machines, which offer reliable performance in difficult processes such as scrap car shredding, optimize the waste management processes of businesses.

Redmonster scrap metal shredder provides great convenience in industrial waste management with its high efficiency, durability and user-friendly design. Scrap metal shredder, iron shredder, scrap iron shredder, aluminum shredder and other models are indispensable parts of the metal recycling process. These machines contribute to environmental sustainability and optimize the waste management processes of enterprises.

High Efficiency Redmonster Scrap Iron Shredder Machine

Redmonster Scrap Iron Shredder Machine Advantages

The scrap metal shredder provides fast and effective shredding of metals with a combination of high torque and low speed. Thanks to its powerful motors and durable components, it offers high performance even under continuous working conditions. The scrap metal shredder is resistant to harsh working conditions with its robust structure and long-lasting blades and requires minimum maintenance.

With its capacity to process different types of metals such as iron shredder and aluminum shredder, it plays an active role in the recycling of materials such as scrap iron, aluminum and stainless steel. User-friendly control panels and simple design allow operators to use the scrap metal shredder comfortably. It provides safe and uninterrupted operation with its automatic return system and overload sensors.

Scrap metal shredder can be widely used in scrap yards, metal recycling facilities, automobile recycling and electronic waste recycling. Scrap car shredder offers high performance for automobile recycling, especially as a car shredder. These machines contribute to environmental sustainability by accelerating scrap car shredding processes. Scrap car shredder reduces operating costs and minimizes environmental impact by providing energy efficiency.

Iron shredding machine and scrap iron shredding machine play an important role in the recycling processes of businesses by providing durability and high performance. Iron shredding machine prices, scrap iron shredding machine prices and metal shredding machine prices vary according to the features and capacity of the machines. It can also be customized according to customer needs.

Scrap metal shredder optimizes the metal recycling process, providing both economic and environmental benefits. Businesses can make their waste management more efficient by using a ferrous shredder and scrap metal shredder.

Redmonster Scrap Iron Shredder Machine Performance and Efficiency

High Efficiency

Scrap metal shredders accelerate the recycling process by shredding metal quickly and effectively.

Durability and Longevity

Equipped with powerful motors and long-lasting blades, the scrap metal shredder is durable even under harsh working conditions.

.webp)

Compatible with Various Metals

The scrap metal shredder can process many types of metals, including scrap iron, aluminum, stainless steel, car parts and electronic waste.

.webp)

Energy Efficiency

Thanks to its high energy efficiency, the scrap metal shredder reduces operating costs while minimizing environmental impact.

Scrap Metal Iron Shredder Machine Industrial Use and Application Areas

Redmonster scrap metal shredders are powerful machines designed to shred a wide range of metal scraps. Scrap metal shredders effectively process scrap metal in scrap yards and metal recycling facilities, shredding metals to a specific size. This process allows metals to be easily sorted and recycled quickly. Scrap metal shredders are used in a variety of applications, including car recycling, metal recycling, and electronic waste recycling, making metal recycling much faster and more efficient.

The scrap metal shredder machine offers innovative and effective solutions in metal recycling and waste management processes. With its high efficiency, durability and user-friendly features, the scrap metal shredder supports environmental sustainability in the processing of metal waste. The Redmonster series scrap metal shredder optimizes the waste management processes of businesses and minimizes negative impacts on the environment. MT Makina opens the doors to a new era in metal recycling with the Redmonster series.

Machines such as car shredders, car shredders and scrap car shredders offer high performance, especially in scrap car shredding processes. It has the capacity to process various types of metals such as iron shredders and aluminum shredders. Scrap iron shredders provide high efficiency even in difficult working conditions with their durable structure and powerful engines. Iron shredder prices, scrap iron shredder prices and metal shredder prices vary according to the features and capacity of the machines. It provides cost advantages to businesses in the long term. Scrap metal shredders support environmental sustainability by accelerating metal recycling in industrial use and optimize the recycling processes of businesses.

Mobile Crusher | Single Shaft and Double Shaft Solutions

The pallet shredder is a cutting-edge system developed for the safe, rapid, and efficient reduction of wooden pallets generated in industrial areas. Available in various models to suit varying capacities and needs, these machines easily process even the most difficult pallet waste thanks to their powerful rotor structure and specialized blade technology. The shredding system, with its high-torque motor and durable blades, reduces pallets to smaller sizes, ensuring hygiene and significantly reducing waste volume. This reduces storage and transportation costs while also supporting environmental sustainability.

Additionally, shredded pallet waste can be repurposed for biomass energy production, fuel preparation, or recycling processes. Standing out with its durable construction, long-lasting performance, and low energy consumption, the pallet shredder is an ideal solution for production facilities, recycling centers, and logistics storage areas. It provides businesses with high productivity by safely processing not only wooden pallets but also packaging waste and similar materials. Pallet shredder prices offer economic advantages for businesses. By combining high-capacity shredding functions in a single device, it reduces both investment and operating costs. It is a powerful, reliable, and environmentally friendly option for long-term and sustainable waste management.

Mobile Crusher

Technical Specifications

TSV-140

Shredding Area: 1400 x 400 mm

Rotor Length: 1400 mm

Engine Power: 30 kW

TSV-200

Shredding Area: 2000 x 400 mm

Rotor Length: 2000 mm

Engine Power: 55 kW

TSVX-200

Shredding Area: 2000 x 400 mm

Rotor Length: 2000 mm

Engine Power: 45 x 2 kW

OPTIONAL FEATURES

Dual-Engine Design

Mobile Design

Metal Separator

Rotor Cooling System

Automatic Lubrication Unit

Sieves in Different Sizes

Conveyor Screw Applications for Exit

.webp)

Scrap Metal Shredder Machine Video Gallery

Scrap metal shredder provides high efficiency in recycling metals such as iron, aluminum, copper. In this video gallery, you can watch how our machines shred scrap metals with their powerful blade systems, durable structure and industrial usage areas. It offers ideal solutions for recycling facilities and metal processing factories.

.webp)

.webp)