.webp)

Fast and Efficient Processing

The scrap press provides high production efficiency by processing metal waste quickly and continuously. This makes recycling processes faster and more effective.

.webp)

Easy Use and Maintenance

The scrap press machine can be easily operated with its simple and user-friendly control panel. Long maintenance intervals and easy maintenance operations ensure uninterrupted operation of the machines.

.webp)

User Security

The hydraulic scrap press is equipped with advanced safety systems such as emergency stop buttons, light curtains and safety sensors, ensuring operator safety.

.webp)

Energy and Cost Savings

Thanks to compact bales, transportation costs are reduced and energy consumption is optimized. The scrap press reduces the costs of businesses by increasing efficiency in recycling facilities.

.webp)

Ability to Process Various Wastes

The scrap press can process metal waste of different sizes and types with its wide feeding openings and high pressure capacity. It can compress a wide range of materials such as vehicle parts, structural steel, electronic components.

.webp)

Sustainable Solution

The scrap baling press offers an environmentally friendly solution for recycling metal waste, which reduces environmental impact and contributes to sustainable waste management.

.webp)

Use in Different Sectors

Scrap iron press and aluminum scrap press accelerate the recycling process by processing metal waste in many sectors such as automotive, construction, electronics and aviation.

.webp)

Durability and Longevity

Our metal bale presses are manufactured with high quality components. They provide long-lasting use thanks to their durable structures and are resistant to harsh working conditions with their heavy-duty design.

.webp)

High Pressure Capacity

The scrap press machine compresses metal waste under high pressure into compact bales. This reduces the volume of waste, thus reducing storage and transportation costs.

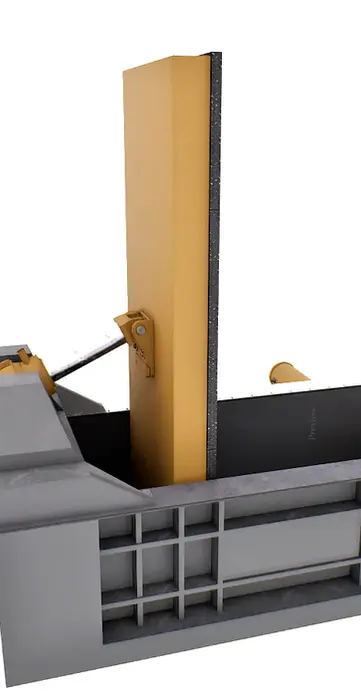

Optimize Metal Recycling Processes with the Use of Scrap Metal Baler

Scrap press machine is an equipment that plays an important role in recycling and industrial production processes. Scrap press compresses metal waste under high pressure and turns it into compact bales, thus providing high efficiency in waste management. Scrap bale press has a wide range of uses from recycling facilities to the automotive industry, from the construction sector to electronics production, and offers great advantages both economically and environmentally.

The metal scrap press can effectively compress large amounts of metal waste with pressing forces ranging from 60 tons to 300 tons. Especially the scrap iron press and aluminum scrap press offer long-lasting use with their durable structures and high-quality components. The hydraulic scrap press easily processes large-sized metal waste with its wide feeding mouth, providing labor savings and ease of operation.

Scrap press manufacturing can be customized according to the needs of businesses in the recycling sector and thus optimize waste management processes. Scrap press prices, scrap iron press machine prices and scrap press machine prices are determined by capacity, pressing power and automation level. Metal scrap press provides cost advantage in metal recycling processes, especially with its high capacity compression power.

Aluminum scrap press and aluminum can press offer ideal solutions for compacting light metal waste. Scrap press machines reduce storage and logistics costs by compacting waste in recycling facilities. Scrap crushing presses accelerate recycling processes by quickly processing large volumes of metal waste.

The top pressing scrap press is an effective machine used especially for compressing large-sized metal waste. The scrap press provides a sustainable and environmentally friendly solution by increasing efficiency in waste management. The metal scrap press provides significant contributions in terms of environmental protection and energy saving while increasing efficiency in recycling facilities. The scrap press is an indispensable recycling equipment that offers both economic and environmental benefits.

Scrap Iron Metal Baler Press Advantages: Efficient and Durable Metal Recycling Solutions

Scrap press machine plays an important role in recycling processes by efficiently processing large volumes of metal waste thanks to its high-pressure compression capacity. Scrap iron press provides maximum efficiency in production processes by working quickly and continuously. Thanks to its durable structure and high-quality components, metal scrap press offers long-lasting use. Hydraulic scrap press allows large metal waste to be processed quickly, while providing long-term shredding performance thanks to its high-quality steel blades.

Scrap bale press compresses metal waste with high pressure into compact bales, which reduces storage and transportation costs. Scrap press provides cost advantages in recycling processes and enables rapid return on investment. Machines such as aluminum scrap press and aluminum can press can process different types of metal waste and offer a wide range of use in sectors such as automotive, construction, electronics, and aviation.

Scrap press machines can be easily managed with a user-friendly control panel and provide uninterrupted operation thanks to long maintenance intervals. Machines such as scrap crushing presses work with high precision and always provide consistent and quality results. The top-press scrap press offers high performance in processing large metal waste and top-press scrap press models for sale offer economical solutions for recycling facilities. Scrap press machines offer both environmental and economic benefits by optimizing recycling processes, thus achieving sustainable waste management and efficiency.

While scrap press manufacturing offers economical and customized solutions according to the needs of businesses, scrap press prices and scrap iron press machine prices vary according to capacity and processing power. Scrap iron press plays a critical role in the recycling of steel components, vehicle parts, white goods and electronic components. In terms of safety, it is equipped with measures such as emergency stop buttons, light curtains and sensors.

Environmentally Friendly Solutions in Recycling with Scrap Press Machine

Scrap Iron Metal Baler Press Performance and Efficiency

High Pressure Capacity

The scrap press machine compresses metal waste under high pressure into compact bales. This reduces the volume of waste, thus reducing storage and transportation costs.

Durability and Longevity

The scrap press ensures long-lasting use thanks to its robust structure and high-quality components. High-quality steel blades remain durable for a long time, extending the maintenance intervals of the machines.

.webp)

Easy Use and Maintenance

The scrap press machine can be easily operated with its simple and user-friendly control panel. Long maintenance intervals and easy maintenance operations ensure uninterrupted operation of the machines.

.webp)

Fast and Efficient Processing

The scrap press provides high production efficiency by processing metal waste quickly and continuously. This makes recycling processes faster and more effective.

Scrap Metal Baler plays an important role in recycling processes by efficiently processing large volumes of metal waste thanks to its high-pressure compression capacity. The scrap metal baler provides maximum efficiency in production processes by working quickly and continuously. Thanks to its durable structure and high-quality components, the scrap metal baler offers long-lasting use. The hydraulic scrap metal baler allows large metal waste to be processed quickly, while providing long-term shredding performance thanks to its high-quality steel blades.

The scrap metal baler compresses metal waste with high pressure into compact bales, reducing storage and transportation costs. The scrap metal baler provides cost advantages in recycling processes and enables rapid return on investment. Machines such as aluminum scrap metal baler and aluminum can baler can process different types of metal waste and offer a wide range of use in sectors such as automotive, construction, electronics, and aviation.

While scrap metal baler manufacturing offers economical and customized solutions according to the needs of businesses, scrap metal baler prices and scrap iron baler prices vary according to capacity and processing power. The scrap metal baler plays a critical role in the recycling of steel components, vehicle parts, white goods, and electronic components. In terms of safety, it is equipped with measures such as emergency stop buttons, light curtains, and sensors.

Scrap metal balers can be easily managed with a user-friendly control panel and provide uninterrupted operation thanks to long maintenance intervals. Machines such as scrap crushing balers work with high precision and always provide consistent and quality results. The top-press scrap metal baler offers high performance in processing large metal waste, and top-press scrap metal baler models for sale offer economical solutions for recycling facilities. Scrap metal balers offer both environmental and economic benefits by optimizing recycling processes, achieving sustainable waste management and efficiency.

High Efficiency in Waste Management with Scrap Press Machine

.webp)

High Pressure Metal Compression | Industrial Scrap Metal Baler Press

The scrap metal baling press is an industrial compression system designed for compact bales of iron, steel, aluminum, copper, and mixed metal waste by compressing them under high pressure in recycling facilities, foundries, metalworking factories, and the scrapyard. Its fully automatic compression, cutting, and wire-cutting features ensure high capacity, uninterrupted, and safe operation. Different press power options from 150 to 400 tons, combined with a high-strength steel body and 300 bar operating pressure, easily handle even the most difficult metal scraps. The advanced control panel, adjustable pressure modes, and automatic feeding system ensure optimal compression performance for different metal types. Equipped with low energy consumption and a powerful hydraulic system, the structure ensures high efficiency and long service life.

Scrap metal baling presses are widely used in metal recycling facilities, the automotive industry, iron and steel plants, foundries, and metal collection centers. With their high energy efficiency, low maintenance, and fully automated system, MT Makina scrap metal baling presses offer an environmentally friendly solution that contributes to sustainable production processes. Our metal presses reduce metal waste volume by up to 80%, reducing transportation and storage costs while also maximizing recycling efficiency.

Metal Bale Press Machine

Technical Specifications

.webp)

MB-400

Main Press Force: 300 Tons

Conversion Time: 90 sec

Bale Size: 500 × 500-W mm

Capacity (Steel): 15 t/h

Capacity (Copper): 17 t/h

Capacity (Aluminum): 5 t/h

Compression Area: 2000 × 2500 mm

Working Pressure: 300 Bar

Overall Dimensions: 7000 × 10000 mm

Engine Power: 150 kW

Weight: 52 tons

MB-500

Main Press Force: 300 Tons

Conversion Time: 90 sec

Bale Size: 600 × 600-W mm

Capacity (Steel): 20 t/h

Capacity (Copper): 25 t/h

Capacity (Aluminum): 5 t/h

Compression Area: 2000 × 2500 mm

Working Pressure: 300 Bar

Overall Dimensions: 7500 × 11000 mm

Engine Power: 150 kW

Weight: 56 tons

MB-600

Main Press Force: 400 Tons

Conversion Time: 90 sec

Bale Size: 800 × 800-W mm

Capacity (Steel): 35 t/h

Capacity (Copper): 40 t/h

Capacity (Aluminum): 15 t/h

Compression Area: 2500 × 3500 mm

Working Pressure: 300 Bar

Overall Dimensions: 10000 × 12000 mm

Engine Power: 180 kW

Weight: 85 tons

OPTIONAL FEATURES

PLC Control System

Remote control

Double and Triple Compression System

Variable Flow Piston Pump

Cycle Time Monitoring

Sound Insulation System

Mobile Unit Options

Security Cages and Light Curtains

MB-150

Main Press Force: 150 Tons

Conversion Time: 90 sec

Bale Size: 250 × 250 mm

Capacity (Steel): 2.5 t/s

Capacity (Copper): 3 t/h

Capacity (Aluminum): 1 t/h

Compression Area: 800 × 1800 mm

Working Pressure: 300 Bar

Overall Dimensions: 3200 × 5500 mm

Engine Power: 37 kW

Weight: 12 tons

MB-170

Main Press Force: 150 Tons

Conversion Time: 90 sec

Bale Size: 300 × 300 mm

Capacity (Steel): 3 t/h

Capacity (Copper): 4 t/h

Capacity (Aluminum): 1 t/h

Compression Area: 800 × 2000 mm

Working Pressure: 300 Bar

Overall Dimensions: 3400 × 7000 mm

Engine Power: 37 kW

Weight: 14 tons

MB-200

Main Press Force: 210 Tons

Conversion Time: 90 sec

Bale Size: 350 × 350 mm

Capacity (Steel): 4 t/h

Capacity (Copper): 5 t/h

Capacity (Aluminum): 2 t/h

Compression Area: 1000 × 2000 mm

Working Pressure: 300 Bar

Overall Dimensions: 3800 × 7000 mm

Engine Power: 37 kW

Weight: 18 tons

MB-300

Main Press Force: 210 Tons

Conversion Time: 90 sec

Bale Size: 400 × 400 mm

Capacity (Steel): 8 t/h

Capacity (Copper): 9 t/h

Capacity (Aluminum): 3 t/h

Compression Area: 1500 × 2500 mm

Working Pressure: 300 Bar

Overall Dimensions: 5900 × 10000 mm

Engine Power: 90 kW

Weight: 34 tons

Scrap Metal Baler Press Video

The scrap metal baling press machine video page offers a detailed look at how the machines, with their high pressing power, transform metal waste into compact bales. The videos, which provide information on the operation, ease of use, and efficiency of different models, guide the decision-making process before investing. They are an effective visual resource for industrial recycling solutions.

.webp)