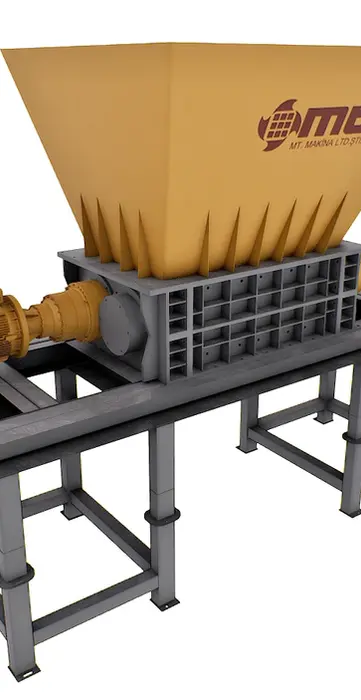

High Efficiency in a Wide Range of Waste with Single Shaft Solid Waste Shredding Machine

Single shaft solid waste shredder stands out with its high efficiency, durability and energy saving features in recycling and waste management processes. Single shaft shredder optimizes recycling processes by processing different materials quickly and effectively with various machines such as plastic shredder, pallet shredder, fabric shredder, paper shredder, pet bottle shredder, scrap tire shredder and shredder.

It provides versatile use especially with machines such as fabric shredding machine, cardboard shredding machine, pvc crushing machine, pallet shredding machine and shinayder plastic crushing machine. Solid waste shredding machine prices offer solutions compatible with different budgets and capacities. The shredding machine can be customized according to the needs of different sectors and has a flexible structure.

Single shaft solid waste shredder, which works as a plastic crusher, recycling crusher and scrap plastic crusher, reduces operating costs while minimizing environmental impacts. It offers long-lasting use with its powerful engines and durable blades. It makes it easier to transport and process large volumes of waste with machines such as tire shredder, plastic crusher and bale shredder.

Single shaft shredder provides high performance with recycling crushers and scrap plastic crushers, and offers sustainable solutions in waste management. In both industrial and commercial areas, machines such as bale shredders and plastic shredders increase recycling efficiency and play a critical role in modern waste management processes.

Advantages of Single Shaft Solid Waste Shredder Machine

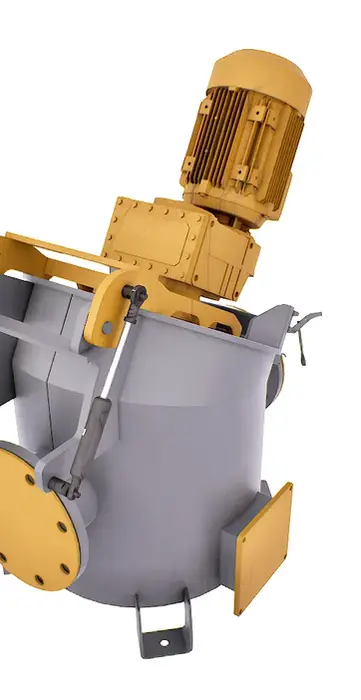

Single shaft solid waste shredder, with its combination of high torque and low speed, provides fast and effective shredding of different materials with machines such as plastic shredder, fabric shredder, pallet shredder and paper shredder. Offering high efficiency with its long rotor, large screen surface and optimized cutter geometry, single shaft shredder plays an important role in recycling and waste management.

The single shaft shredder provides reliable performance even in difficult conditions thanks to its powerful drive motors and durable cutting tools. The hydraulic pressure system ensures that the materials come into contact with the blades more tightly, allowing large and difficult waste to be processed more quickly and efficiently. This system provides high performance in applications such as pallet shredders, scrap plastic crushers and plastic crushers.

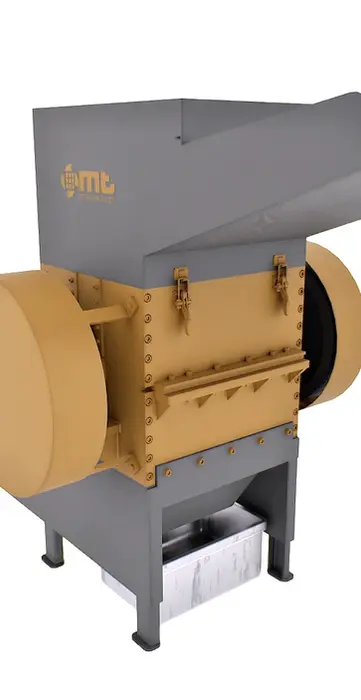

With its special blade design that offers energy efficiency and automatic shut-off feature, it keeps energy consumption at a minimum in machines such as single-shaft solid waste shredders, recycling crushers and scrap tire shredders. Compatible with systems such as discharge augers, conveyor belts, metal separators and pipe magnets, this machine also offers economical solutions in terms of solid waste shredder prices.

Single shaft solid waste shredding machine provides sustainability in waste management and offers high efficiency to businesses by optimizing recycling processes. It also offers effective solutions in different sectors with machines such as plastic scrap crushing machine, bale shredding machine, rubber shredding machine.

A Clean Step to the Future with Single Shaft Shredder Machine

Single Shaft Solid Waste Shredder Machine Performance and Efficiency

High Efficiency

The single shaft shredder optimizes recycling processes by shredding a wide range of materials quickly and effectively.

Durable Knives

The single shaft shredder is equipped with high quality steel blades, ensuring long-lasting use and easily processing hard waste.

Hydraulic Press System

The single shaft shredder machine enables the materials to be processed more tightly with its hydraulic pressing system, thus offering fast and effective shredding.

.webp)

Flexible Application Area

The single shaft shredder is suitable for many industries with its capacity to process various materials such as plastic, wood, paper, cardboard, textile and organic waste.

High Efficiency and Durability with Single Shaft Solid Waste Shredder Machine

Single Shaft Solid Waste Shredding Machines are specially designed for efficient and effective processing of industrial waste. Single shaft shredding machine offers long-lasting use thanks to its main shaft made of high quality steel and durable blades. It processes a wide range of materials quickly and effectively together with machines such as fabric shredding machine, pallet shredding machine, plastic shredding machine.

The single shaft shredder offers uninterrupted operation thanks to the fast and easy replacement of the cutting blades. This feature increases efficiency in all machines such as scrap plastic crushing machines and pet bottle shredding machines. Thanks to the special blade design and energy efficient motors, it reduces operating costs and minimizes environmental impacts.

Single shaft shredder saves energy with features such as automatic shutdown when no material is fed and reverse function when the motor is overloaded. Machines such as plastic crusher, recycling crusher, scrap tire shredder offer high performance in terms of energy efficiency and safety.

Shredding machines offer environmentally friendly solutions in recycling and waste management processes and also provide businesses with advantages in terms of solid waste shredding machine prices. The single shaft solid waste shredding machine stands out as a reliable and sustainable solution for both commercial and industrial uses.

TSH-Single Shaft Solid Waste Shredding Machine

Technical Specifications

TSH-80

Shredding Area: 800 x 1100 mm

Rotor Length: 800 mm

Engine Power: 22–45 kW

TSH-100

Shredding Area: 1000 x 1300 mm

Rotor Length: 1000 mm

Engine Power: 30–75 kW

TSH-130

Shredding Area: 1300 x 1600 mm

Rotor Length: 1300 mm

Engine Power: 45–110 kW

TSH-160

Shredding Area: 1600 x 1800 mm

Rotor Length: 1600 mm

Engine Power: 55–132 kW (2x)

TSH-200

Shredding Area: 2000 x 2300 mm

Rotor Length: 2000 mm

Engine Power: 75–160 kW (2x)

OPTIONAL FEATURES

Different Feed and Output Options

Different Rotor Designs

Dual-Engine Design

Rotor Cooling System

.webp)

Single Shaft Shredding Machine | High Efficiency Waste Management

The single-shaft solid waste shredder is a powerful system developed for the safe and efficient reduction of industrial waste. Its high-performance single-shaft design easily processes even the most challenging materials, providing businesses with significant advantages in waste management processes. Equipped with a durable rotor structure and specialized blade technology, the single-shaft shredder offers long-lasting operation while saving energy and reducing operating costs. These features combine to achieve both high efficiency and economic advantages.

The single-shaft shredder stands out with its versatile applications. It offers a reliable solution for processing metal shredders, pallet shredders, scrap tire shredders, and various other types of solid waste. It accelerates recycling processes by shredding plastic, wood, textiles, and other materials. Standing out with its environmentally friendly design, the single-shaft shredder reduces both storage and transportation costs by minimizing waste. It also contributes to businesses' sustainability goals and offers environmental benefits. It's an ideal choice for long-term investments, offering economical solutions in terms of solid waste shredder prices, scrap iron shredder prices, and pallet shredder prices.

.webp)

.webp)