.webp)

Quick Installation

Mobile crusher accelerates work processes by offering easy installation and rapid commissioning on site.

.webp)

Durability

The mobile crusher, produced from high quality steel, offers long life and continuous operation, which reduces the costs of enterprises and increases efficiency.

.webp)

User Friendly Design

Thanks to its simple control panels and durable structure, the mobile crusher provides easy use for operators and increases efficiency.

.webp)

Environmentally Friendly

The mobile crusher effectively processes recyclable materials, supporting environmental sustainability and reducing waste.

.webp)

Low Operating Cost

With the combination of high torque and low speed, the mobile crusher provides energy efficiency and offers low maintenance costs for long-term use.

.webp)

Flexibility

Capable of processing different materials, the mobile crusher is suitable for various industries such as construction, agriculture, forestry and waste management.

.webp)

Portability

The mobile crusher can be easily transported to the site and offers on-site crushing. This reduces logistics costs and labor requirements.

.webp)

High Efficiency

Mobile crushers speed up the recycling process by processing a wide range of materials quickly and effectively.

A Powerful Solution for Industrial Recycling with High Capacity Mobile Crushers

Our mobile crushing solutions stand out with their portability and ability to process a wide range of materials in recycling and waste management processes. Their robust construction, high performance, and user-friendly design make them suitable for a wide range of industrial applications. By quickly and effectively shredding recyclable materials such as plastic, metal, wood, and paper, mobile crushers increase the efficiency of the recycling process.

Ideal for processing waste from construction and demolition projects, mobile crushers recycle materials such as concrete, wood, and metal. They also offer an effective solution for efficiently processing municipal waste, household waste, and bulky waste. Used in agricultural and forestry management, mobile crushers are used for biomass energy production and composting by shredding plant debris and branches, promoting sustainability in waste management.

Our mobile crushers offer uninterrupted operation with long maintenance intervals, reducing operating costs and increasing productivity. Thanks to their foldable conveyors and portable structure, the mobile crusher is easy to use in the field and offers on-site crushing capabilities. Equipped with high-quality steel blades and easily replaceable cutting blades, the mobile crusher processes materials quickly and efficiently thanks to its combination of high torque and low speed.

With their user-friendly control panels and simple design, our mobile crushers ensure easy operation in industrial facilities. Portable to various industries and sites, the mobile crusher offers a reliable and flexible solution for recycling and waste management processes.

Advantages of Using Mobile Crushers

A mobile crusher breaks down materials quickly and effectively with a combination of high torque and low speed. This feature reduces operating costs and increases productivity. The portable nature of our mobile crushers allows for easy transport to different sites and allows for on-site crushing. This significantly reduces logistics costs and labor requirements.

Mobile crushers are capable of processing a wide range of materials, making them ideal for a variety of industries. Thanks to components made from high-quality materials, our mobile crushers are long-lasting and deliver reliable performance under continuous use. Furthermore, their low energy consumption minimizes environmental impact and reduces operating costs.

Our TSM and CSM series mobile crusher solutions offer businesses a flexible and powerful solution for recycling and waste management, offering high efficiency and durability. Mobile crushers are used in a wide range of industrial and commercial applications, enabling the efficient processing of a variety of waste materials, from construction waste to plastic and metal materials.

On-Site Crushing Solutions with Mobile Crushers

TSM and CSM Series Mobile Crusher Performance and Efficiency

High Efficiency

Mobile crushers speed up the recycling process by processing a wide range of materials quickly and effectively.

Portability

The mobile crusher can be easily transported to the site and offers on-site crushing. This reduces logistics costs and labor requirements.

.webp)

Flexibility

Capable of processing different materials, the mobile crusher is suitable for various industries such as construction, agriculture, forestry and waste management.

.webp)

Durability

The mobile crusher, produced from high quality steel, offers long life and continuous operation, which reduces the costs of enterprises and increases efficiency.

Achieve Flexibility in Recycling with a Portable Mobile Crusher

Mobile crushers offer portability, flexibility, and high efficiency, enabling them to be widely used across a variety of industries. Their robust construction and user-friendly features play a crucial role in recycling and waste management processes. By reducing logistics costs and labor requirements, mobile crushers increase operational efficiency and contribute to sustainable waste management solutions.

Mobile crushers accelerate recycling processes by quickly and efficiently processing plastic, metal, wood, and other recyclable materials. Mobile crushers can be transported to different sites, allowing recycling to be done on-site, reducing labor and costs. Mobile crushers will continue to be a critical tool in industrial recycling for a cleaner and more sustainable environment in the future.

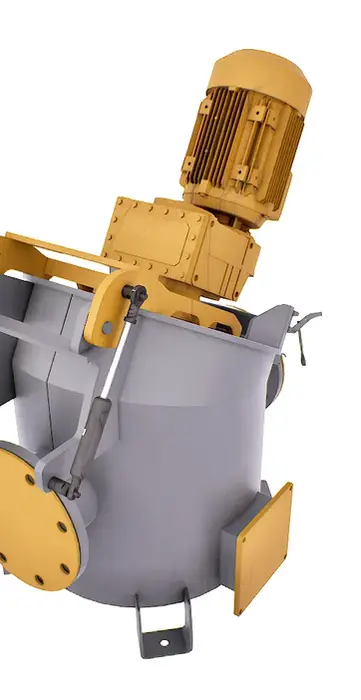

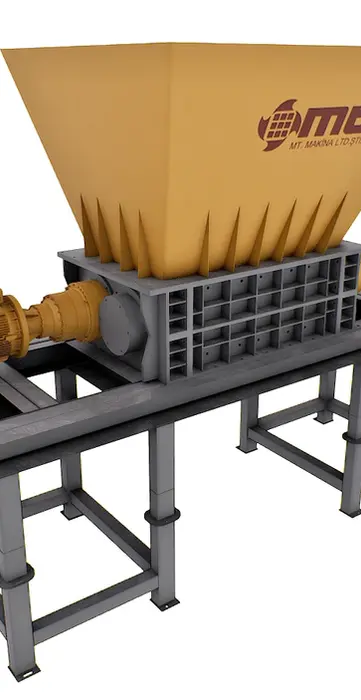

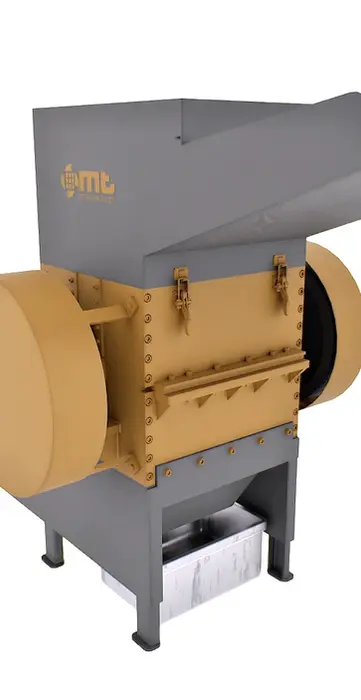

Mobile Crusher | Single Shaft and Double Shaft Solutions

The mobile crusher is a portable system developed for the rapid, safe, and efficient shredding of industrial waste. It is available in single-shaft and double-shaft mobile crusher options to meet different needs. This allows businesses to select the most suitable solution based on waste type and capacity requirements. The single-shaft mobile crusher, with its high-speed rotor system, ensures homogeneous and controlled shredding. It is ideal for rapid processing of smaller and medium-sized waste types. The double-shaft mobile crusher, with its more robust structure and high-torque motors, offers superior performance in shredding large-volume, dense, and difficult waste.

Equipped with a durable rotor structure and heavy-duty blade technology, mobile crushers provide long-lasting operation while saving energy and reducing operating costs. Their portable design also offers the advantage of easy on-site installation and flexible use. Mobile crushers are a reliable solution for processing various materials such as metal, pallets, wood, textiles, and scrap tires. By minimizing waste, they reduce transportation and storage costs and accelerate recycling processes. Mobile crushers, distinguished by their environmentally friendly design, also offer economical solutions in terms of solid waste crusher prices, scrap iron crusher prices, and pallet crusher prices. They are a powerful, efficient, and sustainable option for long-term investments.

Mobile Crusher

Technical Specifications

TSM-150

Shredding Area: 1500 x 1800 mm

Rotor Length: 1500 mm

Engine Power: 400 HP

TSM-300

Shredding Area: 3000 x 2000 mm

Rotor Length: 3000 mm

Engine Power: 600 HP

CSM-150

Shredding Area: 1500 x 1200 mm

Rotor Length: 1500 mm

Engine Power: 400 HP

CSM-200

Shredding Area: 2000 x 1800 mm

Rotor Length: 2000 mm

Engine Power: 800 HP

OPTIONAL FEATURES

Single Shaft and Double Shaft Design

Rotor Cooling System

Automatic Lubrication Unit

Sieves in Different Sizes

Hydraulic Opening Screen System

Folding Conveyor Applications for Exit

Transport System with On-Board or Towing Method

Diesel Engine or Generator Design

Electric Motor or Hydromotor Design

Wheeled and Tracked System

Remote Control System

.webp)

Mobile Crusher Video

Mobile crushers reduce costs and save time by crushing stone, concrete, and construction waste with high efficiency on-site. In this video gallery, you can watch the performance of our mobile crusher models on various material types and learn more about their portable design and powerful crushing capacity. They are ideal for recycling and infrastructure projects.

.webp)