.webp)

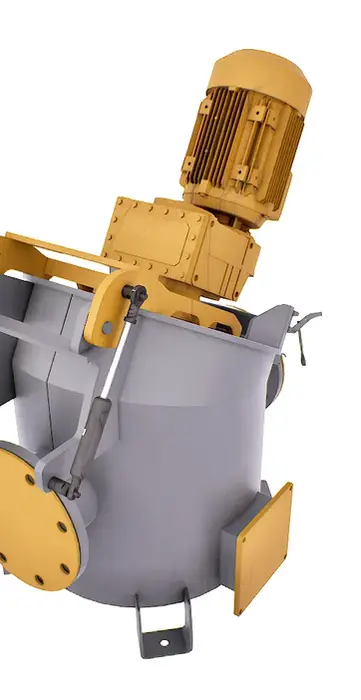

Optional Feeding and Discharging

Feeding and unloading operations can be done with conveyor or helical integration. This speeds up the production process while reducing labor costs.

.webp)

Various Shredding Sizes

The bone crushing machine offers adjustable crushing sizes from 5 mm to 50 mm, adapting to different production needs and offering flexibility to the user.

.webp)

Ease of Maintenance

Thanks to its easy-to-clean structure and adjustable parts, the maintenance processes of the bone crusher machine are fast and practical. This ensures uninterrupted production.

.webp)

Security Features

Thanks to safety features such as overload protection, emergency stop and automatic shutdown, the bone crusher machine ensures operator safety and extends the life of the machine.

.webp)

Hygiene and Durability

Stainless steel body and parts ensure the longevity and durability of the machine while providing a hygienic working environment. This feature ensures reliability in the food and biopharmaceutical industries.

.webp)

Energy Efficiency

Modern bone crushers are equipped with energy-saving hydraulic systems. This increases efficiency while reducing operating costs.

.webp)

Versatile Usage Area

Thanks to its capacity to process various types of bones (such as cattle, sheep, fish, chicken), it offers the opportunity to be used in different sectors such as meat processing plants, pet food manufacturers, food processing businesses, organic fertilizer manufacturers and biopharmaceutical companies.

.webp)

High Efficiency and Speed

Bone crushing machine speeds up the production process by breaking large volumes of bones quickly and effectively. Its high capacity increases daily work volume.

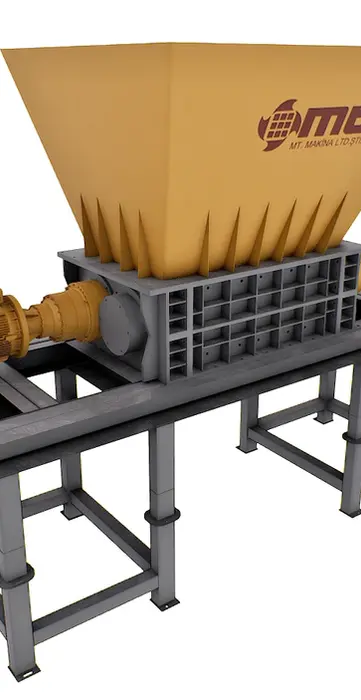

Industrial Solutions with Bone Crusher and Shredder Machine

The bone crushing shredder is a powerful and versatile industrial equipment specially designed to break down animal bones into small pieces. Widely used in many sectors such as meat processing plants, pet food manufacturers, food processing enterprises, organic fertilizer manufacturers and biopharmaceutical companies, the bone crushing machine stands out with its capacity to process both fresh and frozen bones. The bone crushing machine, which can effectively break down animal bones such as chicken, fish, cattle and sheep, can work integrated with the bone grinder machine used to turn the bones into mud after the crushing process.

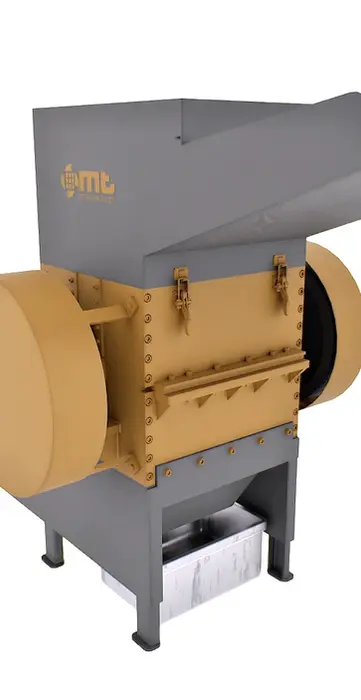

Equipped with a powerful hydraulic system and durable steel blades, the frozen meat shredder facilitates the process by breaking bones in the desired sizes thanks to its high-pressure structure. The bone crusher offers long-lasting and safe use with its wear-resistant stainless steel structure that complies with hygiene standards. The bone crusher, which offers adjustable crushing sizes between 5 mm and 50 mm according to various needs, provides cost advantages to businesses with bone crusher price options in different capacities. Thanks to its low maintenance requirement and easy-to-clean design, the bone crusher facilitates daily cleaning operations.

Equipped with advanced safety features such as overload protection and automatic stop, the bone shredder prioritizes operator safety and reduces potential accidents. This equipment, known as a bone crusher and bone shredder, allows bones to be processed quickly and effectively, while also being suitable for high-capacity production processes. The bone meat shredder, which is heavily preferred in meat processing, pet food and organic fertilizer production, offers efficient solutions for different processing needs and provides cost savings to businesses.

Advantages of Bone Crusher Shredder Machine

The cattle bone crusher is a powerful and versatile industrial equipment specially designed to break down animal bones into small pieces. Usually used in the meat processing industry, animal feed, fertilizer and gelatin production, bone crusher and bone grinder machines turn various animal bones into bone meal to be used as a nutritional supplement. The bone crusher machine stands out with its capacity to process different types of bones such as chicken, fish, cattle and sheep, and offers excellent results in processing both fresh and frozen bones. These devices can work in integration with the bone grinder machine that turns bones into slurry in the production line and cater to various industries such as pet food, organic fertilizer, biopharmaceutical products.

The beef bone crusher usually has a large hopper where the bones are fed into the machine, and the sharp blades or grinding wheels inside break the bones into small pieces. The bone meat shredder machine is durable and long-lasting thanks to its blades made of high-quality alloy steel. In addition, these blades have undergone special heat treatment and have superior wear resistance, which provides the advantage of long-term use for the frozen meat shredder. With the motor overload protection device and power protection that ensures personnel safety, the bone crusher machine is user-friendly in terms of both safety and efficiency.

The bone crusher is ideal for crushing hard materials, especially bone soup, sausage, ham, pet food and biological products. The bone crusher can crush bones into small pieces of 5-80 mm or into a paste-like structure. The bone crusher has a motor overload protection device, thus increasing safety. It provides hygiene with its easy-to-clean feature and can be customized for different areas of use.

Considering its capacity, durability, engine power and safety features, bone crusher prices may vary. The right bone crusher machine selection should be made depending on the business volume of the business and the types of bones processed. With its robust structure, easy cleaning and high efficiency, the cattle bone crusher is an effective solution preferred by businesses in the food processing, pet food production and biopharmaceutical sectors.

Efficient and Safe Bone Processing Solutions with Bone Crusher Machine

Bone Crusher Shredder Machine Performance and Efficiency

.webp)

High Efficiency and Speed

Bone crushing machine speeds up the production process by breaking large volumes of bones quickly and effectively. Its high capacity increases daily work volume.

.webp)

Hygiene and Durability

Stainless steel body and parts ensure the longevity and durability of the machine while providing a hygienic working environment. This feature ensures reliability in the food and biopharmaceutical industries.

.webp)

Ease of Maintenance

Thanks to its easy-to-clean structure and adjustable parts, the maintenance processes of the bone crusher machine are fast and practical. This ensures uninterrupted production.

.webp)

Various Shredding Sizes

The bone crushing machine offers adjustable crushing sizes from 5 mm to 50 mm, adapting to different production needs and offering flexibility to the user.

.webp)

Bone crushing machine is a versatile equipment used in many areas such as food processing, pet food, organic fertilizer, gelatin and collagen production. It is used in food processing and spice production, sausage, meatball, bone broth and spice production; bone crusher makes bones ready for processing by turning them into powder or paste. Bone crushing machine for pet food production produces bone meal, which provides necessary minerals such as calcium and phosphorus in pet food. In organic fertilizer production, crushed bones are used as raw materials for fertilizers used as plant nutrients. In gelatin and collagen production, crushed bones are preferred for gelatin and collagen production, which are widely used in the food, cosmetics and pharmaceutical industries. In addition, calcium and minerals obtained from crushed bones in medical product production are used in pharmaceutical products.

When choosing a bone crusher machine, it is important to evaluate some features according to the needs of the business. Capacity and speed ensure that the production capacity is suitable for the daily work volume. Having a stainless steel structure in terms of durability and material quality offers advantages in terms of long-term use and hygiene. In terms of safety, the bone crusher machine with safety features such as overload protection and automatic shutdown is an ideal option for employee safety. The bone meat crusher with automatic feeding and unloading feature speeds up work processes and reduces labor costs thanks to the integration of the conveyor. It provides efficient use with its easy maintenance, easy cleaning and maintenance features.

Bone crusher machine prices vary depending on various factors such as model, capacity, material quality and conveyor compatibility. High capacity and durable machines provide cost advantages to businesses by offering long-term usage advantages. When evaluating bone crusher machine prices, considering criteria such as energy efficiency, ease of maintenance and suitability for usage areas ensures that a correct investment is made for businesses.

Bone Crusher Shredder Machine Usage Areas

.webp)

Mobile Crusher | Single Shaft and Double Shaft Solutions

The pallet shredder is a cutting-edge system developed for the safe, rapid, and efficient reduction of wooden pallets generated in industrial areas. Available in various models to suit varying capacities and needs, these machines easily process even the most difficult pallet waste thanks to their powerful rotor structure and specialized blade technology. The shredding system, with its high-torque motor and durable blades, reduces pallets to smaller sizes, ensuring hygiene and significantly reducing waste volume. This reduces storage and transportation costs while also supporting environmental sustainability.

Additionally, shredded pallet waste can be repurposed for biomass energy production, fuel preparation, or recycling processes. Standing out with its durable construction, long-lasting performance, and low energy consumption, the pallet shredder is an ideal solution for production facilities, recycling centers, and logistics storage areas. It provides businesses with high productivity by safely processing not only wooden pallets but also packaging waste and similar materials. Pallet shredder prices offer economic advantages for businesses. By combining high-capacity shredding functions in a single device, it reduces both investment and operating costs. It is a powerful, reliable, and environmentally friendly option for long-term and sustainable waste management.

Mobile Crusher

Technical Specifications

TSV-140

Shredding Area: 1400 x 400 mm

Rotor Length: 1400 mm

Engine Power: 30 kW

TSV-200

Shredding Area: 2000 x 400 mm

Rotor Length: 2000 mm

Engine Power: 55 kW

TSVX-200

Shredding Area: 2000 x 400 mm

Rotor Length: 2000 mm

Engine Power: 45 x 2 kW

OPTIONAL FEATURES

Dual-Engine Design

Mobile Design

Metal Separator

Rotor Cooling System

Automatic Lubrication Unit

Sieves in Different Sizes

Conveyor Screw Applications for Exit

.webp)

Bone Crusher Machine Video Gallery

Watch videos about bone crushing machines in this gallery. Learn about the working videos, technical details, areas of use and solutions of our high-performance bone crushing machines designed for food and meat processing plants. Discover our machines that stand out with their stainless body, high capacity, low energy consumption and hygienic structure.

.webp)