.webp)

Providing Protection

Reduces maintenance costs by protecting in-line shredders, pumps and equipment.

.webp)

Environmentally Friendly

The in-line shredder reduces environmental burdens in the wastewater treatment process.

Low Maintenance Requirement

The in-line shredder provides low energy consumption with optimized motor performance.

Energy Efficiency

The in-line shredder provides low energy consumption with optimized motor performance.

Durable Structure

The in-line shredder is resistant to intensive use and has a long service life.

.webp)

Easy Integration

The in-line shredder can be easily integrated into existing wastewater lines.

.webp)

Uninterrupted Flow

The in-line shredder ensures uninterrupted flow in the wastewater line.

.webp)

Clogging Prevention

The in-line shredder reduces the risk of blockages by shredding large solid waste.

.webp)

Easy to Use

The in-line shredder prevents pipe blockages and makes waste management efficient.

Definitive Solution Methods for Sewer and Pipeline Clogging

Wastewater Shredder RotaCut Macerator plays a critical role in preventing blockages and increasing efficiency in industrial and domestic wastewater management. Wastewater Shredder RotaCut Macerator grinds solid materials in pipelines or conveyor systems into small pieces, thus eliminating blockage problems. It works in harmony with systems such as submersible blade pump, submersible blade septic tank pump, submersible wastewater pump with blades, submersible shredder pump, septic tank shredder pump, submersible shredder pump, wastewater pump with blades, submersible shredder pump with blades and submersible wastewater pump with shredder wastewater. RotaCut Macerator prevents blockages in these systems and offers a more efficient wastewater management solution.

Wastewater Crusher RotaCut Macerator facilitates the transportation of wastewater by grinding solids and offers an effective solution especially in septic systems. Macerator RotaCut enables easier management by breaking down wastewater. Providing economic advantages to businesses in industrial wastewater management, this system offers suitable solutions to businesses with options such as grinder wastewater pump prices, blade wastewater pump prices and blade septic tank submersible pump prices.

Macerator RotaCut and wastewater grinders help to manage waste more efficiently by preventing pump systems from clogging. Macerator RotaCut offers a wide range of uses with in-line, open channel and channel type models. Wastewater Shredder RotaCut Macerator contributes to preventing clogging and increasing system performance by providing a reliable and effective solution.

Single shaft and double shaft wastewater grinders: Single shaft grinders are preferred for grinding smaller and softer materials, while double shaft grinders are effective in breaking down hard and large solid materials. Double shaft grinders are preferred more often in industrial areas due to their high torque capacity.

In-Line, open channel and channel type wastewater grinder models: In-Line grinders are integrated into pipelines and prevent blockages by grinding solids in the flow line. Open channel type grinders effectively break down solids in sewer systems with their large flow capacity. Channel type grinders prevent blockages by grinding hard and large materials to maintain uninterrupted flow in the channel. These various wastewater grinder models ensure that systems operate more reliably and efficiently.

Permanent Solutions to Clogging Problems in Industrial Pipelines with Macerator In-Line Wastewater Grinder

In industrial and domestic wastewater management, preventing blockages and increasing the efficiency of the systems are of great importance. Macerator shredder wastewater RotaCut meets these needs and ensures uninterrupted operation in wastewater systems. Macerator shredder wastewater RotaCut effectively grinds the solid materials coming into the pipelines and prevents blockages in pipelines and pumps. It offers superior performance in wastewater management, especially when used with systems such as blade septic tank submersible pumps and shredder blade wastewater pumps.

Macerator shredder wastewater RotaCut breaks solid waste into small pieces, allowing it to be easily transported to other parts of the system. Macerator shredder wastewater RotaCut, used together with blade septic tank submersible pumps and septic tank shredder pump solutions, reduces maintenance costs and increases operational efficiency. Macerator in-line shredder machine ensures the smooth operation of pumps and pipelines by minimizing the risk of blockages.

Macerator shredder blade shredder safely discharges heavy solid objects and stones, extending the life of submersible blade pumps, wastewater pumps, shredder blade wastewater pumps and shredder septic tank pumps, submersible shredder pumps, shredder blade wastewater pumps and wastewater pump blade systems. Macerator shredder wastewater RotaCut provides effective solutions against blockages in pipelines and ensures uninterrupted operation of systems. Using this technology, maximum efficiency is achieved in wastewater management.

Macerator shredder wastewater RotaCut ensures efficient operation of wastewater systems, reduces maintenance costs and offers long-term use. It is the ideal choice for businesses looking for a reliable and sustainable solution in wastewater management.

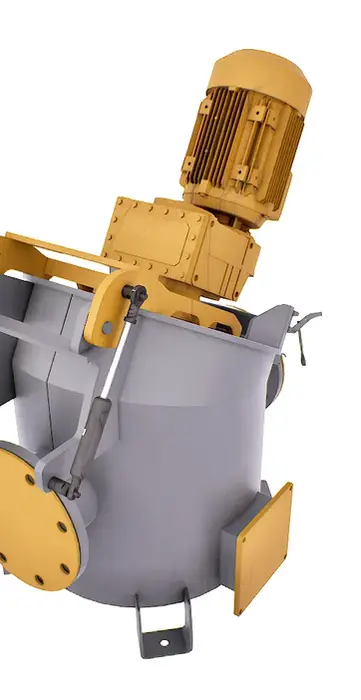

In-Line Shredder Machine Macerator Rotacut Performance and Efficiency

Prevents Clogging

The in-line shredder contributes to the smooth operation of the sewer system by preventing blockages in wastewater pipes.

Environmentally Friendly

The in-line shredder reduces environmental pollution by biologically breaking down organic waste before it goes to landfill.

Long Lasting Knives

The high-quality steel blades used in the in-line shredder are wear-resistant and offer long-term use.

.webp)

High Efficiency

The in-line shredder shreds materials quickly and effectively with a combination of high torque and low speed.

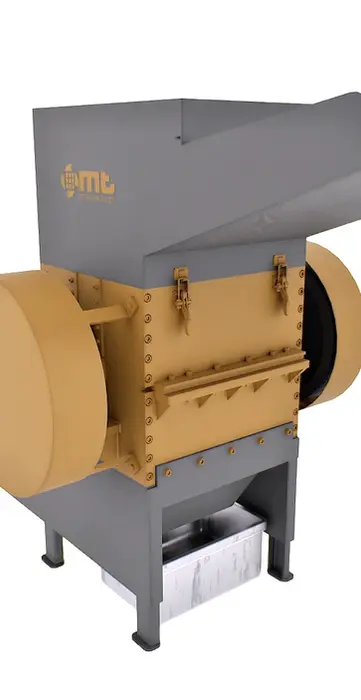

Channel Type and Open Channel Wastewater Shredder Machine: Effective Solution for Pipeline and Sewerage Systems

The channel type wastewater grinder shredder produced by MT Makina offers effective use even in areas with limited space requirements with its resistance to solids and compact structure. The wastewater shredder machine contributes to the prevention of blockages by breaking large volumes of solids into small pieces in sewage systems and to the trouble-free operation of systems such as wastewater pumps. These shredders, which have low speed, high torque and two rows of hardened steel blades, effectively process hard debris such as rocks, wood, plastic, clothing, animal and plant waste. The wastewater shredder works in harmony with bladed wastewater pump types such as bladed submersible pumps and bladed septic tank submersible pumps, ensuring long-lasting and efficient operation of sewage systems.

Channel type wastewater grinder offers wide usage flexibility by being mounted with a steel frame in areas such as sewage pump stations and wet well entrances. It provides a long-lasting solution against wear and corrosion thanks to its optional stainless steel body and durable structure. It protects systems such as wastewater pump, submersible pump with shredder blade and wastewater pump with shredder blade against blockages especially in facilities with high waste load such as nursing homes, sports stadiums, hospitals and urban pump stations.

The intelligent control system ensures that the grinding process continues efficiently and without interruption, while preventing jamming with the load detection feature. The channel type wastewater grinder offers various installation options; it can be easily integrated into the pipeline or open channel system and effectively breaks down solid materials. The optional automatic central lubrication system minimizes the need for maintenance, and provides maximum efficiency with minimum labor thanks to its user-friendly design.

Channel type double shaft wastewater grinders increase process efficiency with a large cutting chamber designed for high flow rates. Thus, downstream equipment such as pumps, valves, centrifuges and heat exchangers are protected from blockages caused by large solids. Channel type wastewater grinders provide a sustainable waste management solution with energy saving and long-lasting operating performance, contributing to reducing the environmental footprint of businesses.

.webp)

Effective Solution for Clogged Sewers and Pipelines Macerator Rotacut In-Line, Open Channel and Channel Type Shredder Machines

In-line shredder machines and Macerator RotaCut systems offer important solutions that increase efficiency in wastewater management and recycling processes. Macerator RotaCut in-line shredder effectively grinds solid materials in domestic and industrial wastewater in wastewater treatment plants, preventing system clogging. In-line wastewater shredder helps protect equipment by ensuring a smooth wastewater flow in treatment processes.

Macerator RotaCut wastewater grinder, in-line shredding machine and channel type wastewater shredding systems safely grind solid materials and prevent blockages in pipelines and pumps. It definitely prevents blockages and deterioration of systems such as wastewater pump blade, blade submersible pump, blade septic tank submersible pump, shredder wastewater pump, blade wastewater pump, submersible pump blade, shredder blade submersible pump, septic tank shredder pump, shredder blade pump, shredder blade wastewater pump and shredder submersible pump. These systems work integrated with wastewater pumps and provide a smooth operation in wastewater management.

The in-line wastewater shredder enables the shredding of plastic, rags and sanitary pads in recycling facilities, facilitating recycling processes and increasing efficiency. When used with RotaCut wastewater pump systems, the macerator minimizes blockage problems and reduces maintenance costs.

The Macerator RotaCut inline shredder is ideal for the efficient grinding and transportation of solid materials, especially in industrial plants. When used together with wastewater pump solutions, it minimizes the risk of blockages and increases operational efficiency. Macerator RotaCut systems provide long-lasting and effective operation in water and wastewater management.

MT Makina helps you achieve maximum efficiency in industrial and domestic wastewater management by offering various solutions such as in-line wastewater shredding machine, channel type wastewater grinder, open channel wastewater grinder and Macerator RotaCut.

In-Line Shredder Machine, Channel Type Wastewater Shredder, Open Channel Wastewater Shredder and Macerator RotaCut Usage Areas

.webp)

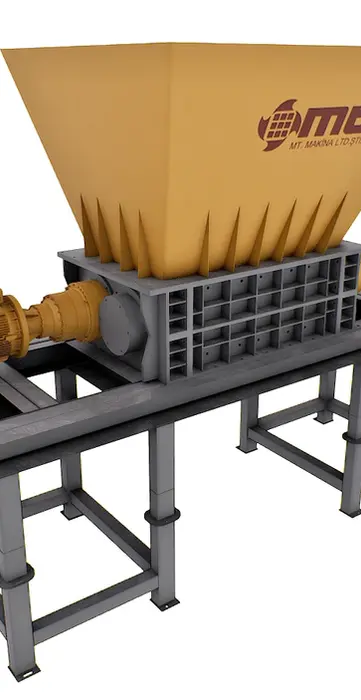

Mobile Crusher | Single Shaft and Double Shaft Solutions

The pallet shredder is a cutting-edge system developed for the safe, rapid, and efficient reduction of wooden pallets generated in industrial areas. Available in various models to suit varying capacities and needs, these machines easily process even the most difficult pallet waste thanks to their powerful rotor structure and specialized blade technology. The shredding system, with its high-torque motor and durable blades, reduces pallets to smaller sizes, ensuring hygiene and significantly reducing waste volume. This reduces storage and transportation costs while also supporting environmental sustainability.

Additionally, shredded pallet waste can be repurposed for biomass energy production, fuel preparation, or recycling processes. Standing out with its durable construction, long-lasting performance, and low energy consumption, the pallet shredder is an ideal solution for production facilities, recycling centers, and logistics storage areas. It provides businesses with high productivity by safely processing not only wooden pallets but also packaging waste and similar materials. Pallet shredder prices offer economic advantages for businesses. By combining high-capacity shredding functions in a single device, it reduces both investment and operating costs. It is a powerful, reliable, and environmentally friendly option for long-term and sustainable waste management.

Mobile Crusher

Technical Specifications

TSV-140

Shredding Area: 1400 x 400 mm

Rotor Length: 1400 mm

Engine Power: 30 kW

TSV-200

Shredding Area: 2000 x 400 mm

Rotor Length: 2000 mm

Engine Power: 55 kW

TSVX-200

Shredding Area: 2000 x 400 mm

Rotor Length: 2000 mm

Engine Power: 45 x 2 kW

OPTIONAL FEATURES

Dual-Engine Design

Mobile Design

Metal Separator

Rotor Cooling System

Automatic Lubrication Unit

Sieves in Different Sizes

Conveyor Screw Applications for Exit

.webp)

Wastewater Shredder Rotacut Machine Video Gallery

Rotacut type wastewater shredder machine prevents system blockages by cutting fibrous and solid waste with high efficiency. It offers effective solutions in biogas plants, sewage systems and industrial wastewater lines. You can watch the working logic and application areas of the machine in detail on our video gallery page.

.png)

.webp)